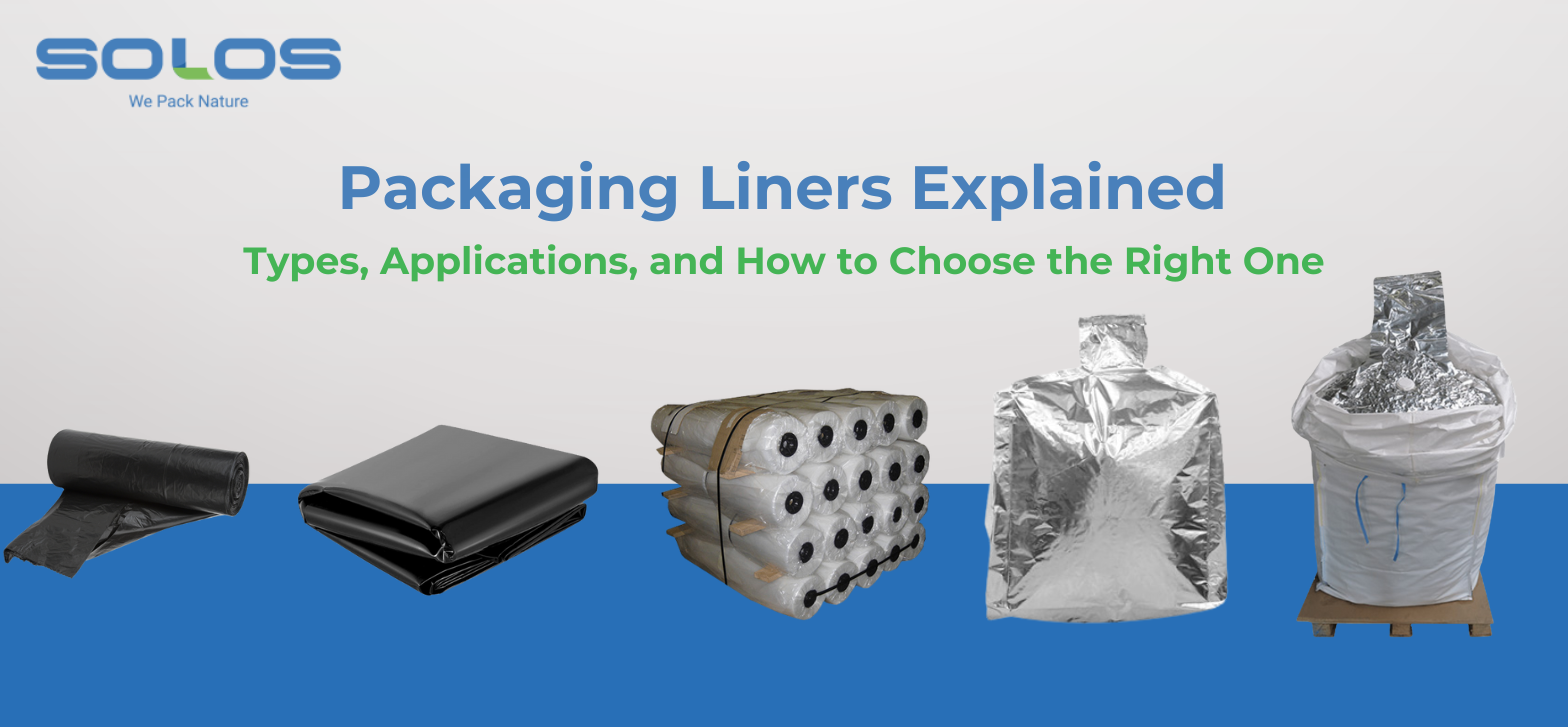

Packaging Liners Explained: Types, Applications, and How to Choose the Right One

In today’s competitive industrial and commercial landscape, product protection has become more critical than ever. Whether it is food grains, chemicals, fertilizers, construction materials, or liquids, ensuring product safety during storage and transportation is essential. This is where packaging liners play a vital role. Packaging liners act as a protective barrier inside bulk bags safeguarding products from contamination, moisture, leakage, and environmental exposure.

As industries increasingly demand hygiene, durability, and sustainability, advanced packaging liner solutions such as FIBC liners, industrial liners, gas barrier liners, and pond liners are rapidly transforming global supply chains. Let’s explore what packaging liners are, the different types available, key applications, and how to choose the right one for your business.

What are Packaging Liners?

Packaging liners are specialized protective layers designed to line the interior of storage and transport containers. They not only protect the product but also improve overall handling efficiency. From bulk bag liners used in FIBC bags to flexible packaging liners for cartons and pond liners for water containment, these liners are engineered to enhance durability, cleanliness, product preservation, and safety.

Modern industries are also shifting toward sustainable packaging liners, made from recyclable or eco-friendly materials, supporting circular economy goals while maintaining performance and reliability.

Types of Packaging Liners

Different industries use different types of liners based on product characteristics, environmental exposure, and regulatory needs. Below are the most widely used options.

1. FIBC Liners / Bulk Bag Liners

FIBC liners (also known as bulk bag liners) are widely used inside Flexible Intermediate Bulk Containers. They ensure product hygiene, prevent moisture penetration, and stop contamination — especially for powders, fine granules, food ingredients, and chemical materials.

Key advantages include:

-

Excellent moisture and contamination protection

-

Suitable for food-grade and chemical-grade materials

-

Enhances storage and transportation safety

-

Helps maintain product purity

FIBC liners are ideal for industries like food processing, agriculture, chemicals, fertilizers, and minerals.

2. Gas Barrier Liners

Some products are highly sensitive to oxygen, humidity, odor, and vapor transmission. For these needs, gas barrier liners are the perfect solution. These liners are engineered to prevent oxygen ingress and protect products vulnerable to oxidation or spoilage.

Industries commonly using gas barrier liners include:

-

Food & beverage

-

Chemicals

-

Electronics

They ensure product shelf life, stability, and quality remain intact throughout shipping and storage.

3. Industrial Liners

Industrial liners are heavy-duty liners designed for harsh environments, rough handling, and bulk industrial applications. They offer chemical resistance, strong tensile strength, and high durability.

They are commonly used in:

-

Mining

-

Construction

-

Waste management

-

Manufacturing

Industrial liners are ideal for hazardous materials, abrasive substances, and bulk industrial packaging applications.

4. Pond Liners

While not traditionally considered “packaging liners,” pond liners are a vital part of industrial liner technology. They help retain water without seepage, support aquaculture, agricultural water storage, landscaping, and industrial water management.

Benefits include:

-

Prevents leakage and seepage

-

Extremely weather-resistant

-

UV-stable

-

Long-lasting waterproofing solution

5. Flexible Packaging Liners

Flexible packaging liners are used inside cartons, drums, containers, and packaging tanks. They provide hygienic handling while maintaining product integrity, especially in the transportation of sensitive or valuable materials.

They are popular in:

-

Food packaging

-

FMCG sector

-

Cosmetic industry

-

Liquid and semi-solid packaging

Applications of Packaging Liners

Packaging liners support a broad range of industries. Some major application sectors include:

-

Food & Agriculture

-

Food grains

-

Sugar, salt, flour

-

Spices and ingredients

-

Animal feed

-

Organic produce

Packaging liners prevent contamination, ensure hygiene, and maintain freshness.

-

Chemical & Fertilizer Industry

-

Powders

-

Chemicals

-

Fertilizers

-

Hazardous substances

They protect against reaction, contamination, and moisture damage.

-

Construction & Industrial Applications

-

Cement

-

Aggregates

-

Minerals

-

Sand & bulk material transport

Industrial liners withstand heavy loads and rough handling.

-

Water Retention & Environmental Protection

Pond liners and similar industrial liners support:

-

Agriculture reservoirs

-

Fish farming

-

xLandscaping ponds

-

Water retention systems

How to Choose the Right Packaging Liner

Selecting the right liner depends on product type, environment, regulatory needs, and budget considerations. Here are the key factors to evaluate.

1. Understand Your Product

Consider:

-

Solid, liquid, powder, granular, or chemical

-

Sensitivity level

-

Hygiene requirements

2. Check Environmental Exposure

Will the product face:

-

Moisture?

-

Oxygen exposure?

-

Heat or UV?

-

Chemical reaction risks?

Choose gas barrier liners, polyethylene liners, or industrial liners accordingly.

3. Evaluate Packaging Format

Your liner must suit your packaging system:

-

FIBC bags → FIBC liners

-

Drums & cartons → flexible packaging liners

-

Water containment → pond liners

4. Consider Regulatory Requirements

Industries like food require:

-

Food-grade certification

-

Hygiene standards compliance

-

International quality specifications

5. Look for Durability & Cost Balance

A good liner should provide:

-

Long-term reliability

-

Tear resistance

-

Cost efficiency

-

Ease of handling

Sustainable Packaging Liners – The Future Ahead

With growing global sustainability awareness, sustainable packaging liners such as recyclable liners, reusable liners, and eco-friendly packaging liners are gaining massive popularity. Businesses are now prioritizing:

-

Reduced carbon footprint

-

Recyclable materials

-

Circular economy compliance

-

Eco-smart packaging solutions

Manufacturers are developing advanced liners that deliver strength, performance, and environmental responsibility together.

Conclusion

Packaging liners are far more than just a protective layer — they are a critical component in ensuring product safety, quality retention, operational efficiency, and regulatory compliance. From FIBC liners and industrial liners to polyethylene liners, pond liners, and gas barrier liners, each liner type serves a unique purpose across industries.

By understanding applications, material properties, and performance requirements, businesses can select the right packaging liner solution to protect their products and strengthen their supply chain.

Choose reliable, high-performance, and sustainable packaging liners with Solos Polymers, your trusted partner for global-standard packaging protection solutions.